Single-Step Fabrication of High-Performance Extraordinary Transmission Plasmonic Metasurfaces Employing Ultrafast Lasers

Did you know that the properties of conventional optics can be mimicked, or even surpassed, with so-called metasurfaces?

Due to the progressive miniaturization of technologies such as mobile phone cameras, optical circuits or detection technologies, optical metasurfaces (compact by definition) are becoming one of the most promising key components for the development of next-generation lightweight devices.

In particular, plasmonic metasurfaces based on the extraordinary optical transmission (EOT) effect can be designed to efficiently transmit and modify a specific band of light, having applications in important technological fields, such as multispectral imaging, biological and chemical detection, or color screens.

However, due to their size (smaller than the wavelength of light), although they can be manufactured today, EOT metasurfaces require techniques called nano- and microlithography, based on several steps carried out in clean rooms, firing thus its cost.

Work

In this work, the scientific team formed by the Laser Processing Group of the IO-CSIC and the College of Engineering, Mathematics and Physical Sciences of the University of Exeter, proposed and experimentally demonstrated a new one-step process for rapid fabrication of EOT metasurfaces using ultrafast laser writing. Unlike lithographic methodologies, this new technique allowed the creation of EOT devices without the need for clean rooms and without generating chemical waste.

(a) Schematics of a typical lithographic process for micro- and nanopatterning of EOT metasurfaces, consisting of several fabrication steps. From left to right: After depositing a thin metal film, a photosensitive layer is spin coated on top of the surface and exposed to photon or electron lithography to modify the solubility of the exposed regions. These regions are then removed using a developer, followed by a wet or dry etching process to remove material from the exposed regions. The process ends by removing the remains of photosensitive material and chemical residues, typically in acetone.

(b) Alternative fabrication routine proposed in this work, consisting of direct laser ablation by surface scanning with pulsed and ultrafast lasers.

(c) Macroscopic view of one of the processed samples, showing six laser-processed 4 mm2 areas. Insets show a light microscope and scanning electron microscopy (SEM) image, confirming the expected micrometric geometric features.

With this technique, in just a few minutes and using a pulsed laser on 40 nm thick gold films, arrays with microholes with an area of 4 mm2 were fabricated, which act as transmission metasurfaces extraordinary.

With this they demonstrated how, by modifying only three parameters of the manufacturing stage (that is: the energy of the laser pulse, the speed of the laser and the beam formation slit), they were able to control both the period Λ, and the diameter or the ellipticity of the microholes, and therefore the optical characteristics of the so-called extraordinary transmission effect of resonances.

Comparing the performance of the fabricated metasurfaces with their theoretical performance it was shown that all the fabricated devices behaved as expected, confirming the high performance, flexibility and reliability of the proposed fabrication method.

These findings could provide the basis for the industrial mass production of EOT metasurfaces, as well as the birth of new branches of research towards the laser fabrication of metasurfaces with alternative functionalities, and in a single step.

What are metasurfaces?

Metasurfaces consist of two-dimensional distributions of building blocks whose sizes and periodicity are less than the wavelength. These can be designed to modify the properties of light falling on them at will. Unlike conventional optics, the ability to manipulate light offered by metasurfaces is not based on propagation effects, but rather comes from abrupt amplitude and phase discontinuities imposed on an incident light beam, and produced by collective resonances and/or or localized caused by the blocks that make up the metasurface.

These block arrays can be specifically designed to mimic and even exceed the capabilities of classic optical devices, with the added benefit of being lightweight, compact and therefore easily integrable.

Within the range of possible functionalities offered by these two-dimensional arrays, plasmonic metasurfaces based on the effect of extraordinary optical transmission (EOT) have attracted much attention in recent years, as such devices are expected to play an important role for example in the generation of compact devices for biological or chemical detection, structural color generation or multispectral imaging.

What is the phenomenon of extraordinary optical transmission (EOT)?

The EOT phenomenon consists of a specific frequency band of light being transmitted through a matrix (the metasurface) made up of periodic subwavelength openings in an (optically) thin sheet. In particular, the high transmission peaks appear near the so-called Wood’s first anomaly, that is, in the boundary between the diffractive and subdiffractive optical regimes. The cause of this phenomenon has been studied in detail in recent years and is attributed to the coupling of resonances typical of isolated openings, combined with periodic network systems.

Therefore, the transmission amount, bandwidth, and spectral position of the EOT effect can be controlled at will by adjusting both the geometric parameters (i.e., aperture size, shape, and periodicity), as well as the material and thickness of the thin film as well as its substrate.

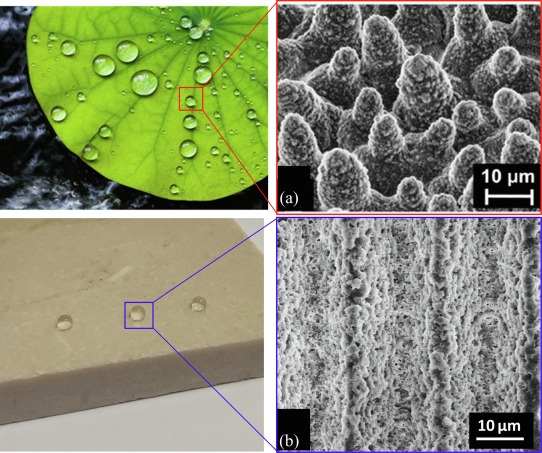

Ultra-fast laser processing

These metasurfaces have been produced thanks to ultrafast laser processing (ULP). This technique can be one of the most promising routes towards clean, large-scale production of nano- and micro-patterned devices, since, as we have said, it is based on single-step procedures that can dispense with polymer masks and contaminants. as well as clean rooms. Using sub-picosecond laser pulses, the pulse energy required to trigger ablation can be reduced while achieving sharp contours on a wide variety of materials including soft and brittle ones.