Multiscale ultrafast laser texturing of marble for reduced surface wetting

Did you know that marble can be made to repel water like some plants?

At the Institute of Optics, the Laser Processing Group investigates, among other things, how to modify the properties of materials with laser, emulating the characteristics special features of some surfaces of animals and plants found in nature.

The study

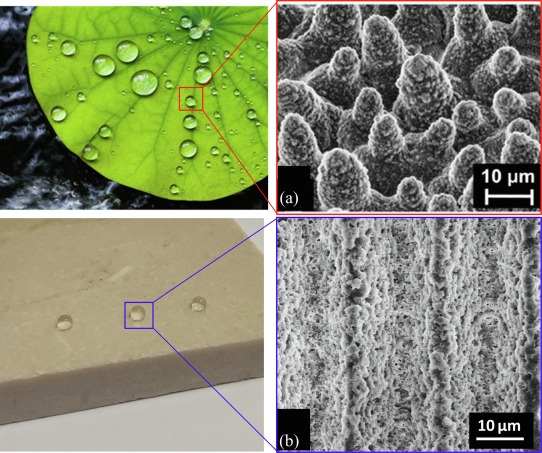

In this article, the research team has treated samples of Crema-Marfil Coto® marble with a femtosecond laser. With this technique, they have succeeded in producing groove patterns of tens of microns on the surface, also covered by another smaller pattern in the form of nanometer-sized scales. This treatment subsequently triggered a chemical reaction that made the marble surface repel water.

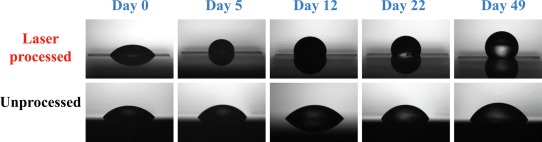

Therefore, laser processing triggers two different effects: an “initialization” of the chemical state of the surface that becomes much more reactive (probably due to thermal decomposition of CaCO3 on the nearby surface of the laser-treated region), which favors the hydroxylation and the adsorption of CH pollutants and, on the other hand, a significant increase in roughness.

In nature the case of the surfaces of lotus leaves is similar, the leaves have a surface with a special shape and are also covered by epicuticular waxes.

The study of the surface during this time allowed to understand the individual contributions of the roughness of the surface on the one hand and of the chemical evolution on the other. The team found that trenches with a spacing of Δ = 20 µm show the greatest initial improvement in hydrophobicity, attributed to micro-roughness. However, taking into account the evolution over time associated with chemical reactions, the best results were obtained for Δ = 30 µm, where the effective surface area is maximized. The mechanisms responsible for the improved water repellency proved to be robust and durable during cleaning.

Why marble?

Marble is a natural material that has been widely used throughout history and up to the present day, where it occupies a prominent place in different market sectors related to architecture and decoration, among others.

However, its durability is impaired by any acidic substance and it is more difficult to clean than other materials.

Most of the substances that are harmful to the quality of its surface and its aesthetic appearance are water-based liquids or acidic or basic substances soluble in water. Therefore it would be a major improvement if the water repellency of marble could be improved.

Chemical coatings are generally used to protect surfaces, but the use of coatings often involves problems associated with adhesion or durability, cracking, or yellowing of the coating over time.

The work has been a collaboration of the Laser Processing Group of the CSIC Optics Institute, the Levantina company and mineral associates, the Materials Physics Department of the UCM Faculty of Physics and the Surface Nanotechnology group of the Institute of CSIC Materials Science of Seville