Far-UV reflectance and stress of narrowband AlF3/LaF3 multilayers

Did you know that to make new discoveries in space you need better mirrors for ultraviolet light?

What is a narrowband coating?

Narrow-band means that the mirror will only reflect light of certain wavelengths, so that they can be separated from other wavelengths that are not of interest for the study.

LUMOS science requirements include scanning for very weak signals in the far ultraviolet, which will necessitate an improvement in the optical performance of narrowband far ultraviolet coatings compared to pioneering instruments.

Astrophysics, solar physics and atmospheric physics can also benefit from space observations in the far ultraviolet, since it contains a large number of spectral lines that can help increase knowledge of the local Universe.

The research work

As we have already said, far ultraviolet narrowband coatings generally consist of multilayers of two materials with contrasting refractive indices and low absorption in configuration of Brag. Fluorides are normally used because they are the most transparent materials in the far ultraviolet.

The research team, made up of staff from the Thin Film Optics Group (GOLD) evaluated the performance of the new AlF3/LaF3 multilayers in far ultraviolet prepared by thermal evaporation at 250 °C and compared this performance with MgF2/LaF3 multilayers, which were previously investigated by the same research group.

Far UV reflectance, stress and the influence of substrate materials were investigated, along with multilayer stability over time when stored in a desiccator at low humidity levels.

The coatings were deposited on both fused silica and CaF2 crystals. The new AlF3/LaF3 multilayers exhibited reduced stress compared to the previous MgF2/LaF3 ones, which allowed increasing the thickness of the multilayer without crack formation. This will make it possible to prepare multilayers with a greater number of sheets, and, therefore, with a higher yield.

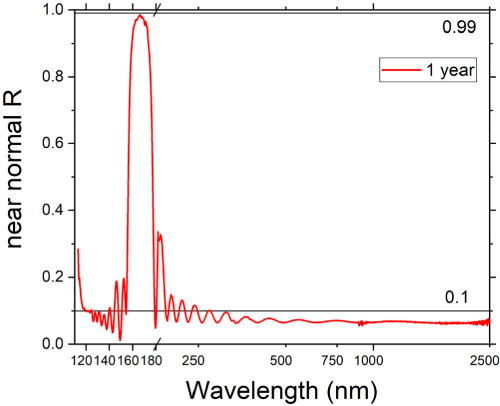

The new AlF3/LaF3 multilayers also suffered a lower reflectance decay with time compared to the MgF2/LaF3 multilayers. The multilayers when manufactured showed a maximum reflectance close to 100%, and most of the AlF3/LaF3 multilayers maintained a reflectance of 99% after several months of storage.

Other applications

Narrow-band coatings in the far ultraviolet are also useful for many other fields. Petawatt laser beamlines, thermonuclear fusion reactors, or the semiconductor industry can also benefit from the use of effective reflectors in the far ultraviolet, a type of light for which almost no material serves as a mirror.

Stress of the multilayer and influence of the substrate materials

The fluoride layers have to be deposited by vacuum evaporation on a hot substrate (250 ºC). This hot fabrication results in less porosity in the layer, as the density of the materials in the layer increases and therefore reduces the space for water or contaminant molecules, which could decrease the performance of the coating over time.

Tensile stress in coatings

Layers deposited by thermal evaporation undergo stresses on cooling, which can alter the shape of the substrate and can also induce cracking and/or delamination of the coating. Most of this stress is thermal in origin when the fluoride coating is deposited on a heated low expansion substrate such as fused silica. This is due to the large difference in the coefficient of thermal expansion between the substrate and film materials, which results in greater shrinkage of the coating when it cools from deposition temperature to room temperature.

The detrimental effect of stress increases with the thickness of the accumulated coating and thus with the number of layers.

The maximum number of bilayers before crack generation for the new AlF3/LaF3 multilayers was found to be ~18-20 (~1000 nm total thickness), which is considerably higher than the number for the MgF2/LaF3 multilayers that were evaluated in a previous investigation, which was ∼13 (~650 nm total thickness). This may be due to the fact that AlF3 has a lower coefficient of thermal expansion than MgF2, and therefore a lower contrast with the coefficient of expansion of the fused silica substrate.