Comparative analysis of silk fibroin membranes fabricated with different cross-linking methods: processing and characterization

- The study compares the properties of a wide variety of silk fibroin membranes fabricated by different cross-linkings.

- Silk fibroin membranes have interesting properties for use in ophthalmology and other biomedical fields.

Madrid / January 13, 2025

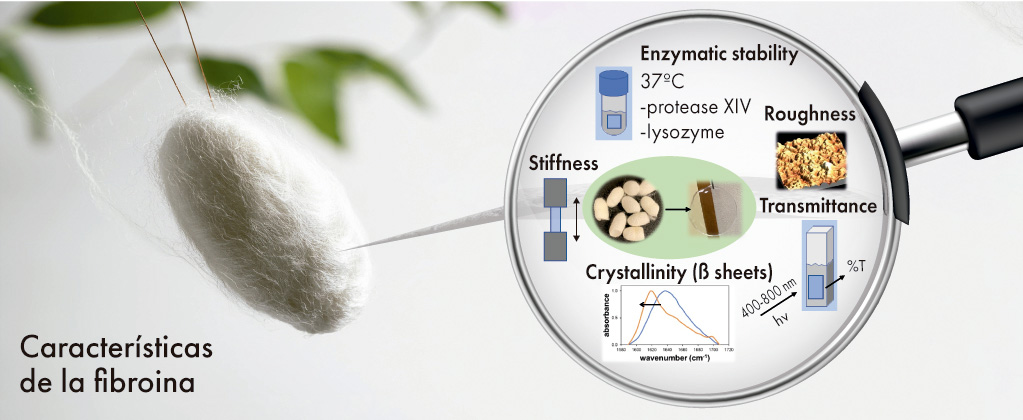

Researchers from the Instituto de Óptica del CSIC and the Center for Visual Science at the University of Rochester have published a study comparing the properties of silk fibroin membranes produced using different physical cross-linking methods. The analysis covered stability, transparency, roughness, and other mechanical and structural properties, with a focus on biomedical applications, especially in ophthalmology. This study provides a comprehensive characterization that will facilitate the selection of suitable materials for various applications.

Latest news

Next Thursday, April 24th, scientific coffee with Hugo F. Martins

The talk is titled "Distributed Optical Fiber Sensing signal processing for seismic applications" And it will be held on Thursday the 24th at 11:00 a.m. in the center's Conference Room Madrid / April 22, 2025The April Scientific Café of the Month will be hosted by...

In order to ensure the consistency of the study and to be able to compare the properties of the materials with each other, the researchers fabricated ten types of silk fibroin membranes, as well as one uncross-linked membrane as a control. To do this, they used silk cocoons produced by silkworms under controlled conditions. Silk fibroin was obtained from the cocoons through a meticulous extraction protocol that includes degumming, dissolution, and purification of the fibroin. Finally, the membranes were fabricated under controlled temperature and humidity conditions, using water as solvent. The optical transparency, enzymatic stability, water absorption, surface roughness and mechanical properties of the membranes were then evaluated. FTIR spectroscopy was also used to study the secondary structure of the proteins. This allowed the degree of cross-linking or proportion of beta sheets to be related to the physical and mechanical properties of the membranes.

What is silk cocoon degumming?

Degumming is a fundamental process in obtaining silk fibroin, the main component of silk used in biomedical applications. The silk cocoon produced by the silkworm is composed of two main proteins: fibroin, which forms the silk fibers, and sericin, a gummy protein that wraps the fibroin fibers and acts as a glue.

Degumming (usually carried out using heat and chemicals) consists of removing sericin to obtain pure fibroin fibers, which are those with the mechanical, optical and biocompatible properties desired in this work. The degumming process is crucial because sericin can cause immunological reactions, so it is important to remove it completely to obtain a material suitable for use in medicine and biotechnology.

Controlling the time and conditions of degumming affects the final quality of the material, so it is important to optimize this process to obtain high-purity fibroin.

IO-CSIC Communication

cultura.io@io.cfmac.csic.es

Related news

Thursday, February 29 scientific coffee with Víctor Rodríguez López

Madrid / February 12, 2024The following Scientific Café entitled "After 200 years: a new method of visual graduation" will be held. This talk will...

Diagnosis of ocular diseases by ocular biomechanics

Madrid / January 24, 2024Tomorrow, January 25, researcher Judith Birkenfeld will give a talk at the Fernández Vega Foundation.Judith Birkenfeld,...

SureVision research project, one of the 10 projects of technology companies supported by CSIC in 2023

Madrid / January 18, 2024The SureVision project of our colleague from the Visual Optics and Biophotonics Group, Víctor Rodríguez, has been one of...