Propagation dynamics of the solid–liquid interface in Ge upon ns and fs laser irradiation

The Laser Processing group has achieved a new breakthrough in laser pulse irradiation on germanium. The dynamics of melting and solidification of the layer melted with laser have been determined.

The laser processing of materials

Due to its ability to modify the surface morphology and certain physical properties of materials in a controlled way, laser processing with fast and ultra-fast pulses is used in many applications, such as photovoltaics, nanophotonics or optoelectronics.

For all these applications, it is important to have a precise understanding of the mechanisms of light/matter interaction, especially near phase change thresholds (eg, fusion and ablation). Given the fast (nanosecond) or ultrafast (pico and femtosecond) nature of the mechanisms involved, excitation-sampling techniques have been developed and applied in the last decades in different materials and excitation conditions.

What is the excitation-sampling technique?

The excitation-sampling technique allows us to study ultrafast phenomena inside matter, such as the movement of atoms or the excitation of electrons, thanks to very short laser pulses.

To do this, a very short and intense laser pulse, the “excitation”, is sent onto a material to excite it. A second weaker pulse, the “sampling”, is sent right after and what happens to it will give us information about the effect of the first pulse. By changing the time interval between the first and second pulses, we can reconstruct the evolution of the excitation over time and thus “film” it with femtosecond resolution.

This technique is based on the high temporal resolution monitoring of a specific optical property of the material of interest (such as the refractive index, reflectivity or light transmission) after or during laser irradiation. Given the direct relationship of this property with the structural phase (solid, liquid or gaseous) and the temperature of the material, its temporal evolution allows knowing the way in which it melts, solidifies or evaporates depending on the energy of the laser pulse, as well as measuring the refractive index of the phases of the hot solid and non-solid material.

However, until now it was not possible to measure the thickness of the molten layer of Ge with this technique because the amount of light reflected by the molten material does not vary with its thickness (think of a surface of mercury).

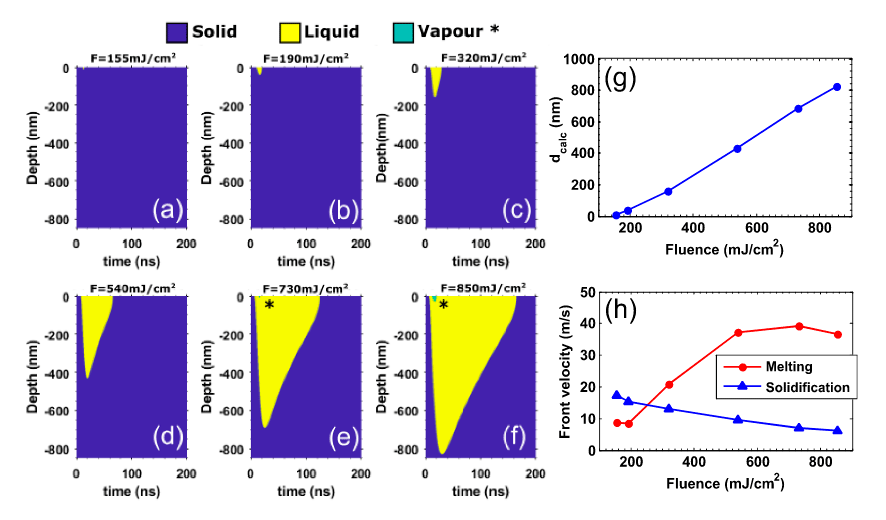

In this work, the research team has presented an alternative method to determine the evolution of the thickness and the rate of advance of the molten layer after laser irradiation, by combining real-time reflectivity measurements with theoretical thermodynamic calculations solved using < a href="https://en.wikipedia.org/wiki/M%C3%A9all_of_the_finite_elements">a finite element technique. For this, the theoretical dynamics of fusion and solidification caused by short (ns) and ultrashort (fs) laser pulses in Germanium have been studied. Through real-time reflectivity measurements and microscopy images with femtosecond resolution, they have experimentally determined the durations of the molten layer as a function of the pulse energy and have compared them with the results obtained by theoretical calculations.

In this way, using the durations of the molten layer measured experimentally, they have been able to indirectly calculate the evolution of the thickness of the molten germanium layer as a function of time, as well as the average rates of fusion and solidification, which otherwise would not be measurable at through excitation-sampling experiments.

The melting and solidification rates of germanium have also been calculated. For fusion with nanosecond pulses, maximum speeds of 39 m s−1 were obtained and for subsequent solidification the maximum speeds were 16 m s-1. For femtosecond pulses, solidification speeds of up to 55 m s-1 were achieved and weak signs of amorphization were found, suggesting that the minimum solidification speed needed to achieve complete amorphization is above 55 m s-1.

What is amorphization?

Amorphization is a rapid solidification process, the speed is such that its atoms are not arranged in an orderly manner. In this way, the amorphous solid has different properties, for example, it can be harder than the crystalline solid.

This is a collaborative project between the Laser Processing Group of the CSIC Institute of Optics, the Department of Applied Physics of the Autonomous University of Madrid, and the University of Exeter College of Engineering Mathematics and Physical Sciences.

Related News

The Institute of Optics joins the celebration of 11F

Full and equal access and participation of women and girls in science and technology Madrid / January 31, 2025In recent decades, the international...

Optoplasmonic tuneable response by femtosecond laser irradiation of glass with deep-implanted gold nanoparticles

Ion implantation of Au2+ at MeV energies has enabled the creation of nanoparticles embedded at greater depth, resulting in a Fabry-Perot cavity...

On November 20th, David Grojo from CNRS will give a lecture entitled “New Dimensions Open to Ultrafast Laser Material Modifications”

Madrid / November 13, 2024On Wednesday, November 20th at 11:30 a.m. we will have a seminar organized by the Laser Processing Group in the conference...