Laser-induced direct transfer printing and the future of digital manufacturing

-

Scientists have developed a new way of printing with micrometer precision using lasers, called laser induced direct transfer (LIFT). This new technique allows them to print microelectronic circuits, small biology tests and even in the future body tissues.

-

The new LIFT technique is very versatile and can use many different materials. It also allows design changes to be made during printing, without changing costs.

Latest news

The most common types of these tools are a 3D printer (additive) or a CNC mill (subtractive).

This digital fabrication allows the creation of structures and devices, without the need for masks, master samples or molds. One of the main advantages of this technique is the ability to make design corrections digitally without having to modify the manufacturing process.

Thanks to this, the costs to manufacture a product can be significantly reduced.

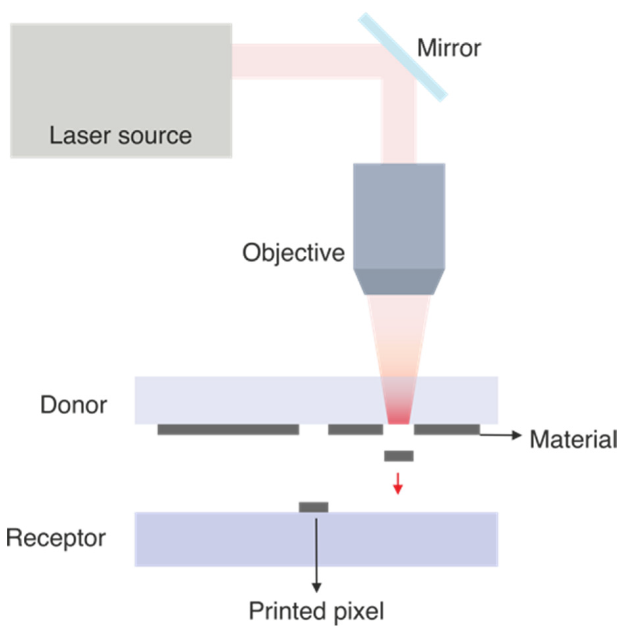

One of the most promising technologies in digital fabrication is Laser Induced Direct Transfer (LIFT), a fabrication technique that enables the transfer of materials from a donor substrate to a recipient substrate with high resolution. In LIFT, the laser is used to volatilize the material of interest and deposit it at user-defined locations, making it a highly precise and flexible method of layer manufacturing (additive manufacturing).

In their published work, the scientists involved have developed a comprehensive description of the current state of the art in LIFT, including a review of recent scientific publications and research on the technique over the last three decades.

By analyzing commercial data of additive manufacturing techniques, they have presented in the work commercial forecasts and possible trends for the LIFT technique in exploitable scientific areas such as electronics, biology and medicine.

Despite the difficulties of developing a new technology, the LIFT technique holds great promise for the future of digital manufacturing, offering a versatile and precise approach that can be applied to a wide range of materials and applications. As the field continues to evolve, it is likely that researchers and engineers will find new ways to harness the power of LIFT to create new devices, structures, and systems that will transform the way manufacturing is done today.

This is a collaborative work between the Institute for Materials Research and Technology of Princeton University, the Daza de Valdés Institute of Optics of the CSIC and the Department of Applied Physics of the University of Barcelona

Related news

The Institute of Optics joins the celebration of 11F

Full and equal access and participation of women and girls in science and technology Madrid / January 31, 2025In recent decades, the international...

Optoplasmonic tuneable response by femtosecond laser irradiation of glass with deep-implanted gold nanoparticles

Ion implantation of Au2+ at MeV energies has enabled the creation of nanoparticles embedded at greater depth, resulting in a Fabry-Perot cavity...

On November 20th, David Grojo from CNRS will give a lecture entitled “New Dimensions Open to Ultrafast Laser Material Modifications”

Madrid / November 13, 2024On Wednesday, November 20th at 11:30 a.m. we will have a seminar organized by the Laser Processing Group in the conference...