Influence of Heat Accumulation on Morphology Debris Deposition and Wetting of LIPSS on Steel upon High Repetition Rate Femtosecond Pulses Irradiation

- New affordable and stable high repetition rate femtosecond lasers are available to the industry

- These high repetition rates pose heat build-up challenges when working on commercial steel

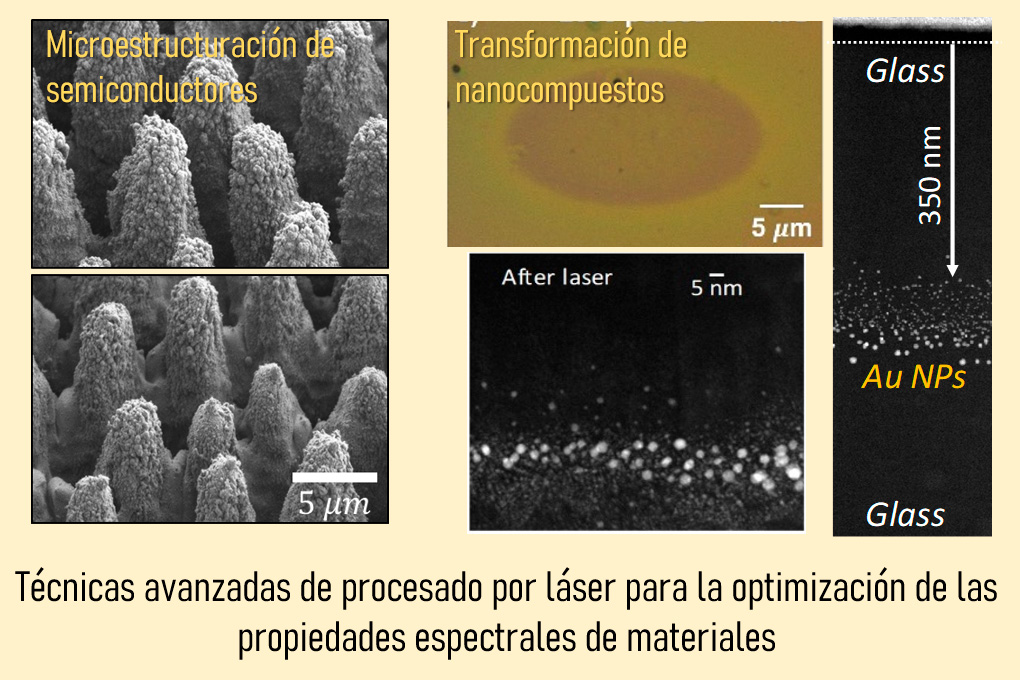

Today, the surface of materials can be modified with a laser so that they can have special properties, such as repelling water or reducing friction. Fabrication of these laser-induced periodic surface structures (LIPSS) over large areas at high speed requires the use of high repetition rate femtosecond lasers, with hundreds of thousands of laser pulses every second.

The use of these lasers to modify materials used in industry, such as steel, presents open challenges related to the accumulation of heat when irradiated above a few hundred kHz, which can lead to significant thermal damage and redeposition of volatilized material extracted by ‘carving’ the material with laser radiation.

Until now, although the problem was known, there were few studies to what extent the repetition rate of the laser influences both the deposition of material and the final shape of the desired LIPSS structure.

Latest news

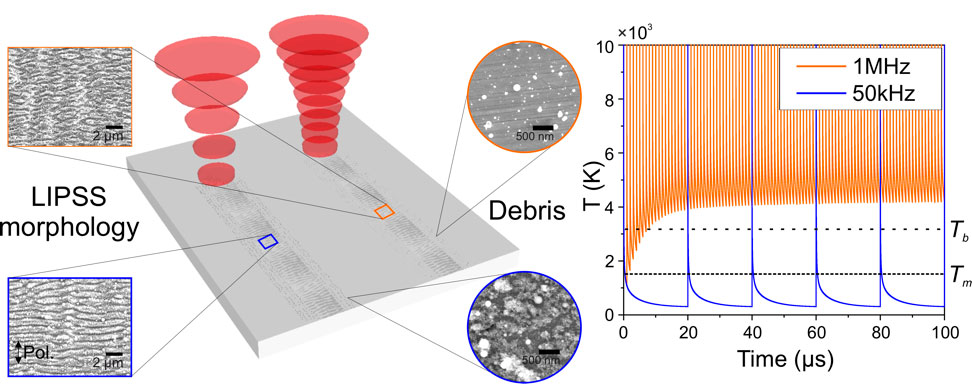

Morphology of irradiated areas on steel at different laser repetition rates produced under different conditions of thermal accumulation.

To search for conditions where thermal buildup implies major morphology changes on irradiated steel, the team developed a theoretical model that calculates heat buildup at different repetition rates.

Laser Induced Periodic Surface Structures (LIPSS)

Laser-induced periodic surface structures can be used for applications in areas such as optics, biology and science. engineering. In general, its manufacturing process consists of a single laser scan over samples under ambient conditions, which is compatible with manufacturing processes for industrial applications in which laser systems for micromachining can easily be incorporated.

The formation mechanism of these structures consists in the formation of an electromagnetic surface wave that interferes with the laser pulse itself, resulting in a modulation of the intensity that is finally deposited preferentially in some places than in others. Its orientation is highly dependent on the polarization state of the laser pulse. Thus, it is possible to generate patterns or drawings that are repeated in the material, and with them the structures that achieve special properties are formed, such as preferential color and directional wetting on the surface, among others. When the repetition period of these structures is close to the laser wavelength (from nanometers to several microns), they are called Low Spatial Frequency LIPSS (LSFL).

Lately, the increasing availability of affordable and stable high repetition rate femtosecond lasers has allowed these structures to be fabricated more quickly, but this comes with heat buildup effects that can drastically affect formation and overall processing performance. In addition, these processes can penetrate further into the material, generating considerable amounts of waste that is then permanently redeposited on the part.

The latter can lead to changes in the performance of the fabricated structures and their functionality, depending on the characteristics of the redeposited particles.

In the study, from the comparison of the simulation results with the experiments in which LIPSS of low spatial frequency are formed, the research team has determined a range of operational repetition rates in which the influence of the accumulation of Heat in the manufacture of LIPSS on steel substrates is negligible, although it is still attractive from the point of view of industrial processing at high speeds.

The findings are relevant for the industrial development of metal processing using high repetition rate femtosecond lasers, allowing the identification of future best designs for the industry.

Related news

Amorphization and Ablation of Crystalline Silicon Using Ultrafast Lasers: Dependencies on the Pulse Duration and Irradiation Wavelength

Madrid / August 29, 2024Researchers from the Laser Processing group at the CSIC Institute of Optics and the LP3 Laboratory belonging to the Aix...

Predoctoral contract offer in the Laser Processing Group (4-year FPI contract)

Madrid / October 7, 2024The Laser Processing group of the Institute of Optics has published a vacancy to carry out a doctoral thesis entitled...

Dynamic restructuring of nickel sulfides for electrocatalytic hydrogen evolution reaction

Madrid / August 2, 2024An international team with the participation of the Laser Processing group of the CSIC Institute of Optics has published in...