A IO-CSIC team visualizes in 3D the temporal evolution of the steel surface during laser processing

-

The work led by scientists from the Institute of Optics provides new keys on the processing of metals by femtosecond lasers using this technique

Madrid / November 23, 2022

A team from the Institute of Optics of the CSIC (IO-CSIC) has studied the processes generated in steel under excitation by ultrashort laser pulses. This research, published in the journal Laser & Photonics Reviews, has allowed scientists to see the evolution of the surface in 3D in terms of its deformation and removal of material, an achievement that provides new clues about this metal processing technique used in industry and the manufacture of materials.

Ultrashort laser processing allows extraordinary modifications to metals, such as changing the color, the way light is reflected, its repulsion to water and its resistance to wear. It also has medical applications because it allows, for example, to manufacture devices that promote cell adhesion and prevent bacterial growth.

Latest news

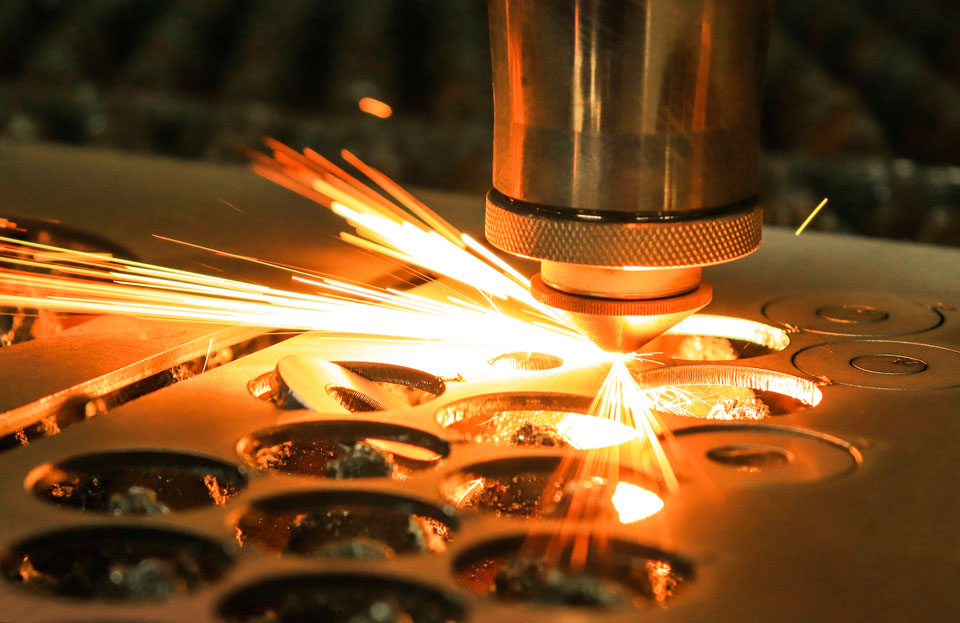

Femtosecond laser machining of materials is today a mature, high-precision technology used in numerous industrial processes. /Wikipedia

“The machining of materials with nanosecond lasers is today a mature high-precision technology, which is applied in the industry in numerous processes. With the arrival of the ultrafast femtosecond laser, an enormous advance has been made, being able to treat the surface of a material without it undergoing much heating, creating clear patterns or drawings at nanometer scales”, explains Jan Siegel, CSIC researcher at the IO.

However, to fully exploit the potential of this technology and achieve the design required in each case, a detailed knowledge of the interaction processes between the laser and matter is necessary.

Picosecond Resolution Microscopy

Scientists have imaged the surface of the material at different times after application of the laser pulse, achieving ultrafast temporal resolution and microscopic spatial resolution. These experimental data have been combined with a theoretical model developed to obtain the 3D structure of the evolution of a material excited by the laser.

“We have studied theoretically and experimentally the changes undergone by a steel sample after applying a laser pulse. We have managed to identify and determine the dynamics of the successive processes of electron excitation, heating, fusion, expansion of the liquid surface and evaporation of part of the metal, in addition to obtaining a 3D reconstruction of the layers of material in expansion during the different stages”, details Yasser Fuentes, first author of the work.

In the strong excitation regime, researchers have observed ultrafast heating of electrons during the pulse, directly followed by energy transfer to the lattice within a few picoseconds, leading to the initial formation of a hot molten material without having had time to expand.

The information obtained in this work will contribute to increasing the achievable precision and the richness of structures that can be obtained by designing pulsed energy deposition schemes.

Alda Ólafsson / CSIC Communication

Related news

The Institute of Optics joins the celebration of 11F

Full and equal access and participation of women and girls in science and technology Madrid / January 31, 2025In recent decades, the international...

Optoplasmonic tuneable response by femtosecond laser irradiation of glass with deep-implanted gold nanoparticles

Ion implantation of Au2+ at MeV energies has enabled the creation of nanoparticles embedded at greater depth, resulting in a Fabry-Perot cavity...

On November 20th, David Grojo from CNRS will give a lecture entitled “New Dimensions Open to Ultrafast Laser Material Modifications”

Madrid / November 13, 2024On Wednesday, November 20th at 11:30 a.m. we will have a seminar organized by the Laser Processing Group in the conference...