Cold sintering of complex-shaped ceramic materials

-

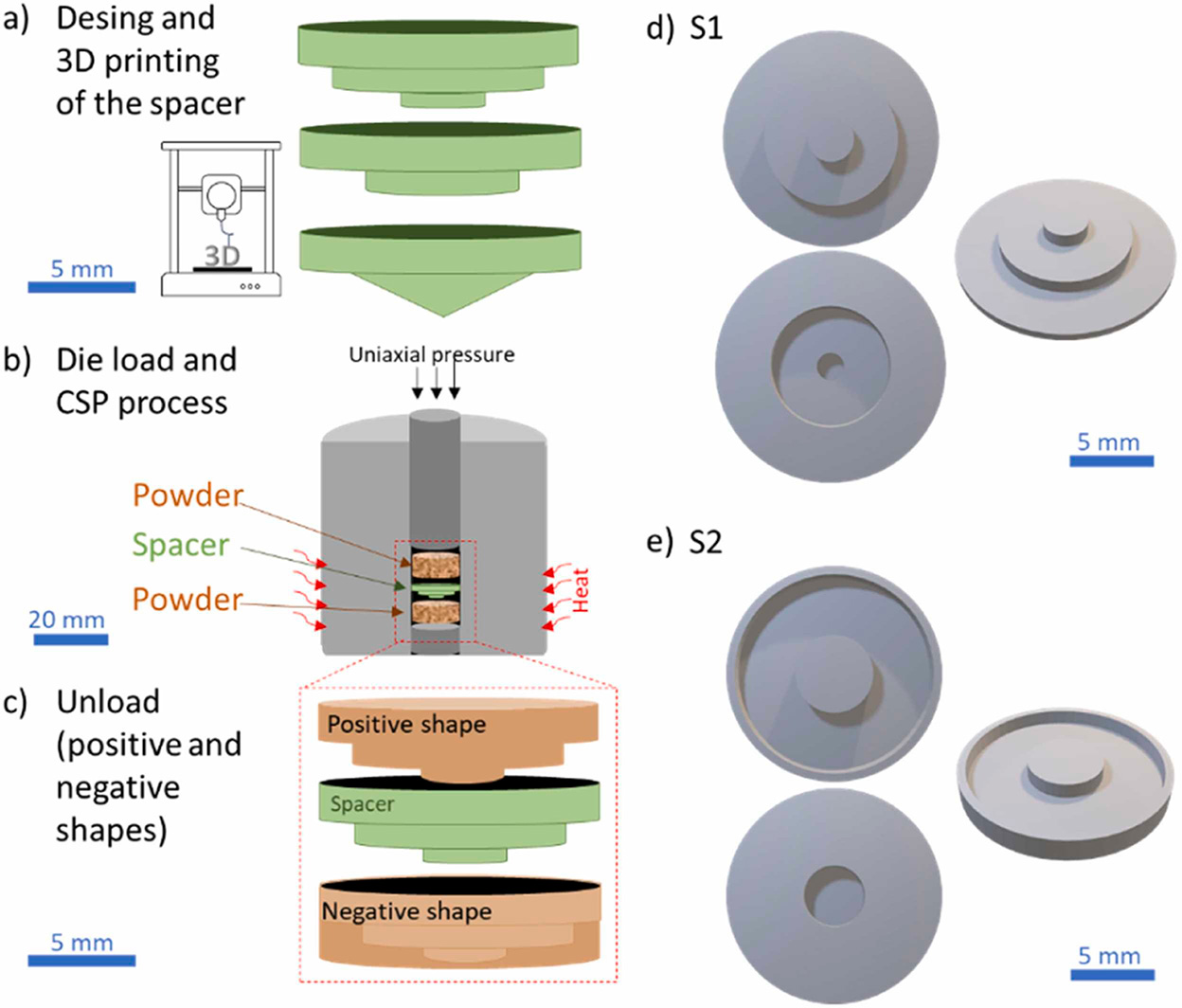

For the first time, dense ceramics with complex shapes have been obtained through the cold sintering process, opening new avenues in advanced materials manufacturing.

-

This innovative approach makes it possible to obtain ceramic materials with intricate shapes and homogeneous microstructures, significantly reducing energy consumption in their production.

Madrid / September 17, 2024

Scientists from the Institute of Ceramics and Glass and the Institute of Optics of the CSIC in collaboration with researchers from the universities of Trento and Padua in Italy have published an innovative study in which the cold sintering of ceramic materials with complex shapes is achieved. This work, a pioneer in its field, demonstrates for the first time the feasibility of producing dense and homogeneous ceramics using this low-energy method, opening up new possibilities in the manufacture of ceramic components with potential applications in various industries.

Latest news

However, until now, cold sintering had been limited to the production of small, simple samples, mainly in the form of discs. The manufacturing of more complex shapes using this method represented a significant challenge due to the difficulty of applying pressure uniformly throughout the sample.

This study addresses that challenge, proposing an innovative approach that achieves cold sintering with the use of removable molds, thus opening new paths in the manufacturing of complex ceramic structures with applications in sectors ranging from biomedicine to construction.

Following this work, the research team has set out to optimise the present cold sintering process to reduce and control the distortions found caused by uniaxial pressing.

Article: Sonia Marín-Cortés, Mattia Biesuz, Subhadip Bhandari, Giorgia Franchin, Esther Enríquez, José F. Fernández and Vincenzo M. Sglavo. “Cold sintering of complex-shaped ceramic materials”. Journal of the European Ceramic SocietyVolume 44, Issue 16. August 2024

IO-CSIC Communication

cultura.io@io.cfmac.csic.es

Related news

Experimental characterization data on aggregates from construction and demolition wastes for the assistance in sorting and recycling practices

Madrid / July 12, 2024Nowadays, the circular economy of construction materials is a challenge that can offer great benefits in environmental, social...

Far UV coatings for liquid-Ar time projection chambers

Madrid / September 22, 2023Liquid Ar (LAr) and liquid Xe (LXe) time projection chambers (TPCs) are used for many applications in neutrino physics...

Formation of hollow silver nanoparticles under irradiation with ultrashort laser pulses

Madrid / March 20, 2024We have studied the formation of cavities in spherical silver nanoparticles embedded in silica, irradiated with fs laser...